Eine unvergleichliche Legierung.

Linear Elastic Nitinol

When Linear Elastic Nitinol is subjected to strain, the stress increase is nearly proportional. This linear performance sets it apart from standard superelastic or shape memory Nitinol, which would deform more easily upon reaching its plateau stress. This product features a stiffer wire that offers greater pushability, primarily required by guidewire applications, along with greater strength without sacrificing 1:1 torque transmission. Linear Elastic Nitinol will recover up to 4% strain, which is not dependent on a temperature induced phase change.

Entwurfsspezifikationen

- Size range 0.0762 mm [0.003 in] to 0.635 mm [0.025 in]

- Linear Elastic Nitinol is available in discrete lengths ranging from 51 mm [2.0 in] to 5 m [197 in]

- Available in all superelastic alloys with NiTi #1 and NiTi #9 being most common

- Surface finishes

- Light oxide

- Dark oxide

- Geätzt

- Gebeizt

- Mechanically polished

- Silk® Nitinol wire

You can learn more about the mechanical performance of Linear Elastic Nitinol using the information below.

Axial tension testing at various temperatures

.png)

Note Exposure to temperatures above 250 °C may alter the mechanical properties of Linear Elastic Nitinol products.

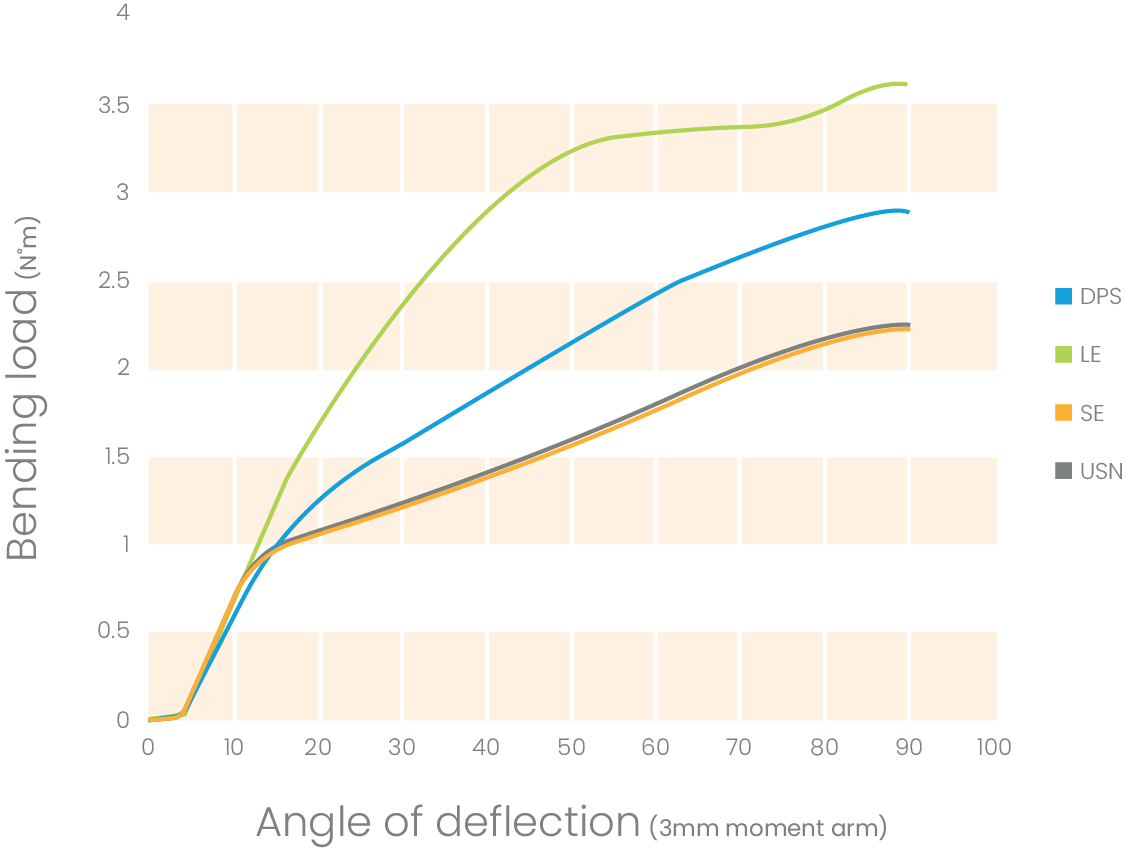

Bend moment comparison of various Nitinol conditions

Axial tension testing of various Nitinol conditions vs. stainless steel

.png)

Typische Endanwendungen

- Führungsdrähte

If your Nitinol product need falls outside of the above parameters, we would be glad to help you. Contact a member of our team: Find your Rep